Sneaker×Decarbonization

My deep love for basketball shoes has shaped not only how I play, but also how I see the world. For me, sneakers are more than just performance gear — they’re personal, almost like an extension of identity. While studying abroad in Canada, I faced financial constraints that forced me to get creative. I began reselling my old shoes to fund new pairs that to purchase leftover sneakers in Outlet mall. I again started reselling them online and school legally with the severe negotiation which was pretty challenging for me and with any leftover profits, I made donations to charities organizations. What began as a personal hustle gradually opened my eyes to a much bigger issue: the way we consume shoes, and the environmental impact hidden behind every pair.

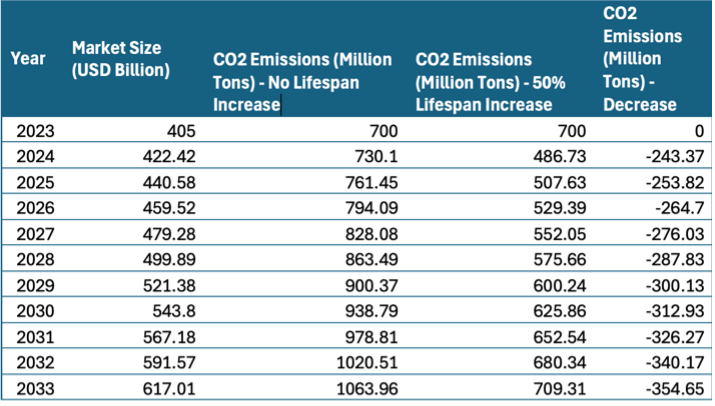

The scale of the global footwear industry is staggering. With over 8.1 billion people on the planet, most owning multiple pairs of shoes, the market was valued at $405 billion in 2023 and is projected to reach $600 billion by 2032. Annually, the world produces around 24 billion pairs of shoes, which collectively emit approximately 700 million tons of CO₂ — with manufacturing alone accounting for about 80% of that. To put it into perspective, this is equivalent to Japan’s 2030 national greenhouse gas emissions target. In Japan specifically, 95% of shoes — amounting to roughly 2,000 tons — are discarded every year. Shoes have become disposable goods, with an average lifespan of just 8 to 12 months, and the materials we rely on — rubber, carbon, polyester — can take up to 30 years to decompose, leaving a heavy environmental footprint.

When I researched how major brands are responding to this crisis, I found that their efforts, though commendable, remain limited. Initiatives like free take-back programs and incorporating recycled materials into new products are a step in the right direction — but they barely make a dent. The reality is, 95% of shoes still end up in landfills. Clearly, a fundamental shift in how we approach the design, use, and end-of-life management of footwear is urgently needed.

In my research, I explored a multi-pronged strategy:

1️⃣ Extending the average lifespan of shoes by 50% (from 12 to 18 months),

2️⃣ Increasing recycling rates to 95%, and

3️⃣ Adopting biomass plastics that are biodegradable and less carbon-intensive.

Let’s break it down.

If the market keeps growing at the predicted 4.3% annual rate, emissions could exceed 1 billion tons by 2032. But if we successfully extend product lifespan by 50%, we could reduce production demand and bring emissions down to around 692 million tons — a roughly 33% reduction.

On the recycling side, pushing the recycling rate to 95% could remove another ~2.19 million tons of CO₂ from the equation, even after accounting for the ~638,400 tons generated during the recycling process. Taken together, these measures could sharply cut landfill waste, conserve raw materials, save energy, and drastically lower greenhouse gas emissions.

Biomass plastics present an additional opportunity. These materials are lightweight, durable, and offer comparable performance to conventional plastics, all while reducing carbon emissions during manufacturing. They also open up exciting design possibilities, making sustainable fashion not just a moral choice, but a creative one. However, their higher production costs remain a potential barrier, highlighting the need for broader consumer education and economic incentives.

To bring this vision to life, we can’t rely on companies or consumers alone. We need a systemic push — international cooperation, regulatory frameworks, and policy interventions. Japan’s Home Appliance Recycling Law, for example, could serve as a model to introduce mandatory recycling schemes for footwear. It’s essential to engage governments, environmental ministries, industry leaders, and even political stakeholders to build the kind of global momentum this issue demands. Looking ahead, innovations like embedding tracking chips into shoes to improve traceability and recycling efficiency should also be on the table.

In the end, the goal of achieving a 95% recycling rate and transforming the footwear industry into a sustainable, circular system isn’t just a technical challenge — it’s a cultural one. It requires a shift in how we value products, how we measure progress, and how we connect personal passion with planetary responsibility. Economic impact studies and policy development are critical next steps, but the core message is clear: with the right strategies, we have a real opportunity to reshape the industry and significantly reduce its environmental footprint.

僕はバスケットボールシューズへの深い愛着があり、それがプレーの仕方だけでなく、物の見方にも影響を与えてきた。スニーカーは単なる道具ではなく、自分の一部のような存在である。カナダ留学中、経済的制約に直面し、工夫を重ねた。古い靴を売って新しいモデルを手に入れ、アウトレットモールで仕入れたスニーカーを許可の下で転売した。学校やネットでの交渉はかなり大変であったが、その結果、多少の利益が生まれ、それを少額だったが事前活動団体に寄付することもできた。この個人的な活動が、やがて靴の消費やその背後にある環境負荷について考えるきっかけとなった。

世界の靴産業の規模は驚くべきものである。世界人口約81億人の多くが複数の靴を所有し、2023年の靴市場は約4050億ドル(約62兆円)、2032年には6000億ドル(約90兆円)に達する見込みである。年間約240億足の靴が生産され、その製造過程だけで約7億トンのCO₂が排出される。これは日本の2030年温室効果ガス排出目標に匹敵する規模である。日本では毎年靴の95%が廃棄され、約2000トンに及ぶ。靴の平均寿命は8〜12ヶ月で、使用されるゴム、カーボン、ポリエステルといった素材は自然分解に30年を要し、環境負荷が高い。

大手ブランドの取り組みを調査したところ、回収プログラムやリサイクル素材の使用といった動きは見られるが、全体の中では依然として限定的である。実際、現状では靴の95%が埋立地に行く。根本的にデザイン、使用、廃棄の在り方を見直す必要があると感じた。

そこで、自分の研究では次の三つの戦略を探った。

1.靴の平均寿命を12ヶ月から18ヶ月に延ばすこと、

2.リサイクル率を95%に引き上げること、

3.バイオマスプラスチックのような環境負荷の少ない素材を採用することである。

靴のライフスパンを50%延ばすことで、生産量を減らし、結果としてCO₂排出量を大幅に削減できる可能性があると考えた。試算によると、今後市場規模が6000億ドルに成長しても、寿命を18ヶ月に延ばせば、CO₂排出量は約33%減少し、約3億4500万トンの削減が見込める。この結果はあくまでシミュレーションではあるが、靴の使い方を見直すだけで大きな環境インパクトが得られることを示唆している。

リサイクル率を95%まで引き上げれば、埋立廃棄物の削減や資源保護、エネルギー節約、温室効果ガス削減といった効果が期待できる。もちろん、リサイクルの過程自体でもCO₂は発生するが、最終的には年間約219万トンのCO₂削減につながると推計される。ただし、効率的なリサイクルシステムを構築するには経済的課題が伴い、これをどうクリアするかが今後の鍵である。

さらに、バイオマスプラスチックのような素材を使うことで、製造段階でのCO₂排出を抑えられるだけでなく、使用後の堆肥化やリサイクルも容易になる。従来の靴に比べても軽量で耐久性があり、パフォーマンスも遜色ない。デザインの自由度が高い点も魅力であるが、課題はコストの高さであり、これが消費者の購買意欲に影響を与える可能性がある。

最終的な実現には、国際協力と法整備が不可欠である。「家電リサイクル法」のように靴のリサイクルを義務化し、メーカー、小売業者、消費者の関心を高める必要がある。各国政府、環境省、経済産業省、主要メーカーへのロビー活動を通じ、グローバルな動きをつくることが重要である。将来的には靴にICチップを埋め込み、流通から廃棄までのトレーサビリティを高めることも検討に値する。95%のリサイクル実現を目指し、持続可能な靴産業の構築に取り組むべきである。経済的影響の分析は、今後の課題として残される。

本研究では、靴産業の持続可能性を高めるための具体策を提示した。これにより、環境負荷の大幅軽減が期待できる。新素材の導入も、環境保護に資するものである。持続可能な循環型経済を実現するためには、国際的連携と効率的なリサイクル体制の構築が必要であり、今後は経済面と法制度の課題に対する研究が求められる。

50% Longer Lifespan Calculations

Step 1: Calculate the emission rate per billion dollars of market size

Emission rate = Current emissions / Current market size

Emission rate = 700 million tons / $405 billion = 1.73 million tons per billion dollars

Step 2: Calculate projected emissions without lifespan increase

Projected emissions = Future market size × Emission rate

Projected emissions = $600 billion × 1.73 million tons/billion = 1,038 million tons of CO2

Step 3: Calculate the impact of increased lifespan

With a 50% increase in lifespan, we can assume that fewer shoes need to be produced to meet the same demand.

Reduction factor = 1 / (1 + 0.5) = 0.667

Step 4: Calculate new emissions with increased lifespan

New emissions = Projected emissions × Reduction factor

New emissions = 1,038 million tons × 0.667 = 692.35 million tons of CO2

Results:

- Without lifespan increase: 1,038 million tons of CO2

- With 50% lifespan increase: 692.35 million tons of CO2

- Emissions reduction: 345.65 million tons of CO2 (33.3% reduction)

95% Recycle Calculations

Baseline Scenario (95% disposed, 5% recycled):

Production of a pair of shoes emits 14 kg CO2 (this is an average figure based on some studies)

Disposal in a landfill emits an additional 3 kg CO2 per pair (due to decomposition and methane release)

Recycling saves about 30% of the production emission

Calculation:

Total production emissions: 24 billion × 14 kg = 336 million tons CO2

Disposal emissions: 22.8 billion × 3 kg = 68.4 million tons CO2

Recycling savings: 1.2 billion × (14 kg × 0.3) = 5.04 million tons CO2 saved

Total emissions: 336 + 68.4 - 5.04 = 399.36 million tons CO2

Proposed Scenario (95% recycled, 5% disposed):

Assumptions:

Recycling process emits 20% of the original production emissions

Recycled material replaces 70% of virgin material in new shoe production

Calculation:

Production emissions remain the same: 336 million tons CO2

Disposal emissions: 1.2 billion × 3 kg = 3.6 million tons CO2

Recycling process emissions: 22.8 billion × (14 kg × 0.2) = 63.84 million tons CO2

Emissions saved by using recycled material in new production:

24 billion × (14 kg × 0.7 × 0.95) = 223.44 million tons CO2 saved

Total emissions: 336 + 3.6 + 63.84 - 223.44 = 180 million tons CO2

Impact on CO2 Emissions:

Baseline Scenario: 399.36 million tons CO2

Proposed Scenario: 180 million tons CO2

Reduction: 219.36 million tons CO2 (about 54.9% reduction)